Table of Contents >> Show >> Hide

- Before You Start: Know What You’re Working With

- Tools and Supplies Checklist

- Safety Notes (Read These Like They’re the Rules of the Table)

- The 11 Steps to Disassemble a Pool Table

- Step 1: Clear the Table and Document Everything

- Step 2: Set Up a Hardware System (So You Don’t End Up With Mystery Bolts)

- Step 3: Remove the Pockets

- Step 4: Unbolt and Lift Off the Rails

- Step 5: Remove the Side Skirts/Aprons (If Your Table Has Them)

- Step 6: Detach the Felt Carefully

- Step 7: Find and Uncover the Slate Screws

- Step 8: Break the Slate Seams (Three-Piece Slate Tables)

- Step 9: Lift and Remove the Slate (This Is the Heavyweight Round)

- Step 10: Save the Shims and Leveling Bits (Tiny Pieces, Huge Impact)

- Step 11: Disassemble the Frame and Legs/Pedestals

- Packing Tips That Prevent Damage (and Tears)

- Common Mistakes to Avoid

- Quick FAQ

- Real-World Experiences: What People Learn After Taking One Apart (Extra Tips)

- Conclusion

Disassembling a pool table is a little like taking apart a fancy sandwich: there are layers, there are hidden fasteners,

and if you rush, something expensive will fall on your foot. The good news? With the right tools, a little patience,

and a couple of strong helpers (seriouslythis is not a solo sport), you can break down a pool table safely for a move,

a renovation, or a “why did I buy a 9-foot table for a 10-foot room?” moment.

This guide walks you through how to disassemble a pool table in 11 clear steps, with practical tips for

protecting the slate, saving your hardware, and setting yourself up for a smoother reassembly later. We’ll cover the

most common home and tournament-style tables (especially slate pool tables), and point out where bar/coin-op

tables can be a little different.

Before You Start: Know What You’re Working With

Slate vs. “Not Slate” (Why It Matters)

Most serious pool tables use slate under the felt. Slate is heavy, brittle, and unforgivingkind of like a

cat that doesn’t know you yet. Many tables have three slate pieces; some have one-piece slate,

which is dramatically heavier and harder to maneuver. If you have one-piece slate and stairs are involved, strongly consider

professional pool table movers.

How to Tell If You Should Hire Pros

- One-piece slate, tight hallways, or stairs

- Antique or high-end table (Brunswick Gold Crown, etc.)

- No helpers who can safely lift and carry heavy parts

- You need it to play perfectly afterward (leveling slate is its own art form)

Tools and Supplies Checklist

Get these together before you remove a single bolt:

- Socket wrench set (common sizes vary by table)

- Power drill/driver with bits (for slate screws and some brackets)

- Flathead screwdriver

- Staple puller (or end-cutting pliers) for stapled felt

- Putty knife or paint scraper (for wax/filler over screws and seams)

- Needle-nose pliers (helpful for stubborn staples)

- Painter’s tape + permanent marker (label parts)

- Zip-top bags or small containers (hardwarelots of it)

- Moving blankets, cardboard, stretch wrap (protect rails, slate, frame)

- Work gloves and safety glasses

- Furniture dolly (optional but helpful)

Safety Notes (Read These Like They’re the Rules of the Table)

- Do not lift slate alone. Use at least 2–3 helpers per slate section.

- Protect your fingers. Rails and slate edges are pinch-point magnets.

- Keep kids and pets out of the work area. This is not a spectator sport.

- Wear gloves and closed-toe shoes. Because gravity is undefeated.

The 11 Steps to Disassemble a Pool Table

Step 1: Clear the Table and Document Everything

Remove balls, racks, table cover, bridge, chalkanything loose. Then take photos:

the pockets, underside, rail bolt locations, and any labels or brand plates. These pictures become your

“how did this go back together?” insurance policy later.

Pro tip: Put painter’s tape on each rail section and write where it came from (e.g., “Head rail,” “Right side rail”).

You’ll thank yourself when everything looks identical on the floor.

Step 2: Set Up a Hardware System (So You Don’t End Up With Mystery Bolts)

Grab zip-top bags and label them by part:

Pockets, Rails, Slate screws, Legs, Aprons/Skirts.

Drop bolts into the right bag as you remove them. If your table uses different bolt lengths, add notes like

“long bolts = corners.”

Step 3: Remove the Pockets

Most pockets attach from underneath with screws, bolts, staples, or clips. Get under the table with good lighting.

Remove fasteners carefully and support the pocket as it loosens so it doesn’t drop and tear.

If you have a ball return system (common on bar-style tables), you may also see tracks or plastic channelsremove these

after pockets if they block access.

Step 4: Unbolt and Lift Off the Rails

Rails are typically held on by rail bolts accessed from underneath. Use your socket wrench and remove bolts systematically.

Keep one hand supporting the rail from above if possibleonce the last bolt is out, rails can shift.

Some tables have rails in multiple sections; others lift off as larger assemblies. Either way, carry rails

like you would a long, fragile piece of furniture: slow, steady, and not through a doorway at a weird angle.

Step 5: Remove the Side Skirts/Aprons (If Your Table Has Them)

Many tables have decorative panels (aprons) attached to the cabinet. These can block access to slate screws or frame bolts.

They’re usually held with screws from inside the cabinet or brackets underneath. Remove them and label each piece

(e.g., “Left apron”).

Step 6: Detach the Felt Carefully

Felt is attached one of two ways: staples or glue.

-

If stapled: Use a staple puller and work around the perimeter. Go slowly to avoid tearing the cloth.

As the felt loosens, roll it neatly (don’t fold if you plan to reuse it). -

If glued: Start at a corner and peel back gently in a slow, steady motion. Glued felt often stretches or tears,

and many people replace it after a move anywaydon’t feel guilty if your felt “retires” here.

Keep the felt clean: wrap it in a plastic bag or clean sheet so it doesn’t pick up dust and grit.

Step 7: Find and Uncover the Slate Screws

Slate is typically secured with screws/bolts that may be hidden under wax, filler, or tiny plugs. Use a putty knife or scraper to

carefully remove filler until the screw heads are exposed. Don’t gouge the slatethink “gentle archaeology,” not “demolition.”

Once exposed, remove screws with a drill/driver or appropriate bit. Bag and label these screws separately.

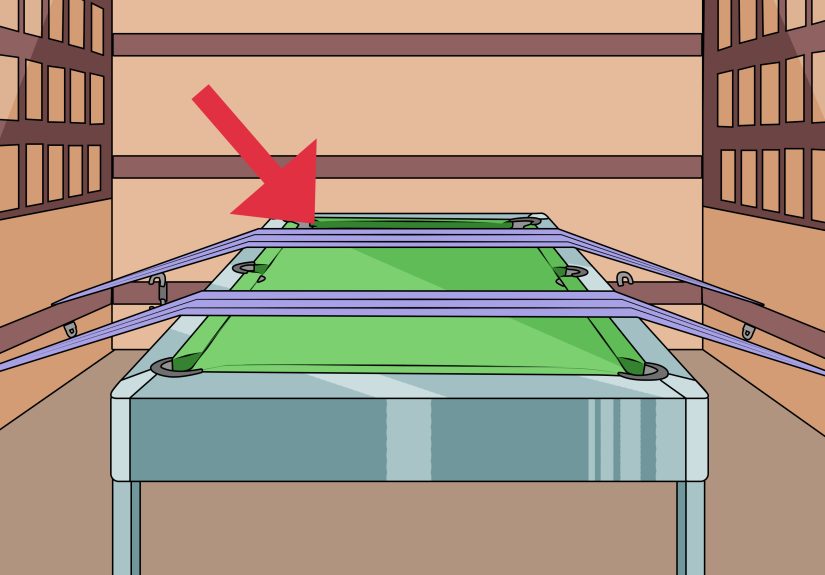

Step 8: Break the Slate Seams (Three-Piece Slate Tables)

If your table has three slate sections, the seams are often filled (wax or putty). Carefully scrape seam material away.

You’re aiming to separate the slate sections without chipping edges. Use gentle pressure and patience.

If you feel strong resistance, double-check for missed screws near the seamhidden fasteners are common.

Step 9: Lift and Remove the Slate (This Is the Heavyweight Round)

With all screws removed and seams cleared, it’s time to lift. Use at least two helpers per slate section

(more is better). Lift straight up and set slate down on padded blankets.

- Carry slate vertically when moving through tight spaces, with edges padded.

- Never twist slate while carryingit can crack under uneven stress.

- Protect corners and edges with cardboard + wrap.

If it’s one-piece slate, treat it like a giant, fragile stone door from a movieexcept there’s no treasure, only regret if it drops.

One-piece slate is a strong reason to hire pros.

Step 10: Save the Shims and Leveling Bits (Tiny Pieces, Huge Impact)

Under the slate you may see wood shims or small leveling materials placed at key points.

These are crucial for re-leveling. Collect them, label where they came from (photos help), and bag them together.

Skipping this step can turn reassembly into a puzzle where the prize is a ball that always rolls to the same sad corner.

Step 11: Disassemble the Frame and Legs/Pedestals

With slate off, the remaining cabinet/frame becomes much lighter (still awkward, but less “crush your dreams” heavy).

Remove bolts that secure legs or pedestals. Some frames separate into panels; others stay mostly intact.

Wrap legs and cabinet pieces in moving blankets to prevent scratches. Keep bolts in a labeled bag.

At this point, you’ve successfully turned a pool table back into a bunch of furniture partscongratulations, you’ve unlocked

“giant adult LEGO” mode.

Packing Tips That Prevent Damage (and Tears)

- Slate: Pad edges, keep pieces upright when transporting if possible, and avoid stacking heavy items against it.

- Rails: Wrap each rail section separately; protect corners and pocket openings.

- Hardware: Tape labeled bags to the part they belong to (or keep all bags in one “pool table hardware” bin).

- Felt: Roll it around a cardboard tube or keep it flat/rolled in a clean bag.

Common Mistakes to Avoid

- Rushing the felt removal: Stapled felt tears easily if you yank instead of lift staples.

- Forgetting hidden screws: Miss one slate screw and you’ll wonder why the slate won’t budge.

- Mixing hardware: “Extra bolts” usually means “missing bolts later.”

- Ignoring shims: Leveling is hard enoughdon’t sabotage yourself.

- Trying to move slate like regular wood: Slate chips and cracks if handled casually.

Quick FAQ

Can I disassemble a pool table by myself?

You can do some steps solo (labeling, removing accessories, organizing hardware), but slate removal should be done with helpers.

If you’re alone, stop before the slate step and call in reinforcements.

Do I have to remove the felt?

On most slate tables, yesbecause the felt covers slate screws and seams. If you’re planning to refelt anyway, this is a great

time to replace it after the move.

How long does disassembly take?

For a typical home slate table, many DIY teams finish disassembly in a few hours depending on experience and table design.

The first time always takes longermostly because you’ll be labeling things like a careful museum curator.

Real-World Experiences: What People Learn After Taking One Apart (Extra Tips)

People who disassemble a pool table for the first time often describe the experience with the same three emotions:

confidence, surprise, and then deep respect for gravity. The confidence shows up at the start“How hard can it be?

It’s just wood and felt!”right up until the moment someone realizes the playing surface is basically a carefully leveled

rock slab wearing a green sweater.

One of the biggest “aha” moments is how much a pool table depends on tiny details. The table looks like one object,

but it behaves like a system: rails align to pockets, slate sections align to seams, and shims quietly do the hard work of

making your shots feel fair. DIYers often say the small stuff surprised them the most: hidden slate screws under wax,

staples that seem to multiply when you’re on your knees pulling them out, and the way a single unlabeled bolt can turn

reassembly into a guessing game.

Another common experience: the room layout suddenly matters. People learn quickly that the “best path out of the room”

is rarely the path you imagined. Rails can be long and awkward, slate corners can chip on door frames, and stairs

add complexity fast. Many movers recommend a quick walkthrough before you lift anything heavymeasure doorways,

clear rugs, and decide where each part will rest while you work. The best disassemblies feel calm and organized; the worst

ones feel like a sitcom where everyone is holding something heavy and yelling, “Waitwhere do we put this?”

Felt removal is another rite of passage. People who plan to reuse felt often go into it with big hopes and then discover

the felt has opinions. Stapled felt can come off cleanly if you’re patient and methodical; glued felt may peel unevenly

or stretch, and that’s when many folks decide a fresh refelt after the move is worth the peace of mind. The takeaway

that shows up again and again is simple: if the felt is old, stained, or loose, treat the move as a reset.

It’s easier to transport parts when you’re not stressed about preserving cloth that’s already lived a full life.

Finally, experienced DIYers often say the “secret weapon” isn’t a special toolit’s labeling and photos. A few minutes

of documentation at the beginning prevents hours of confusion later. People who bag bolts by section and label rails by position

tend to have a smoother reassembly (and fewer leftover parts that look important but can’t be identified). If you want the table

to play well again, the real lesson is this: disassembly isn’t just taking it apartit’s preparing for a successful rebuild.

Conclusion

Disassembling a pool table is totally doable when you take it step-by-step: clear and label, remove pockets and rails,

lift the felt, uncover and remove slate screws, carefully separate and move the slate, and then break down the frame and legs.

The key themes are patience, organization, and help for the heavy lifting. Follow the 11 steps above,

and you’ll protect the parts that matter mostespecially the slatewhile making your eventual reassembly far less stressful.