Table of Contents >> Show >> Hide

- Why the Idea Is So Tempting (and Why It’s Not Automatically Genius)

- Helicopter vs. Quadcopter: Same Spinny Idea, Different Philosophy

- The Core Math You Can’t Dodge: Thrust, Weight, and Disk Loading

- Rotor Interference: When Four Rotors Start Arguing in the Air

- Structure and Vibration: The Part Everyone Underestimates

- Control System Reality: “Motor Mixing” Isn’t MagicIt’s Math with Consequences

- Power and Thermal: The Unsexy Stuff That Determines Whether It Works

- Redundancy and Failure Modes: What Happens When One Corner Has a Bad Day?

- Safety and U.S. Rules: The Part You Don’t Want to Learn the Hard Way

- Design Choices That Usually Work Better Than “Just Bolt Them Together”

- So… Is It a Good Idea?

- Experience Notes: What Makers Commonly Learn When Scaling Up (500+ Words)

- Conclusion

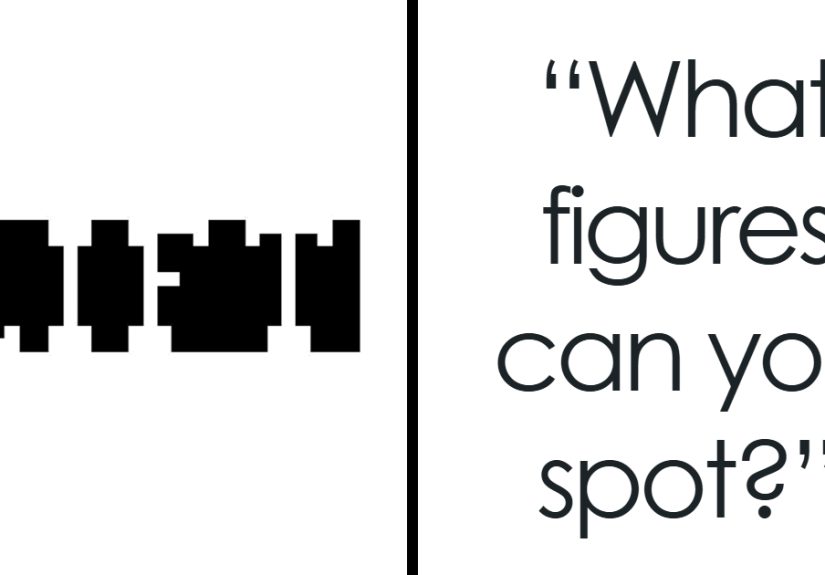

There’s a certain kind of maker-brain thought that hits at 1:07 a.m.: “What if I take four small helicopters… and make one big quadcopter?”

It’s part curiosity, part engineering ambition, and part “my workbench needs a new boss fight.” The idea is surprisingly logical:

a quadcopter is basically four lifting rotors sharing one flight controller, one mission, and one dramatic destiny.

But here’s the twist: scaling up from “four separate rotorcraft” to “one integrated multirotor aircraft” isn’t a LEGO set.

It’s a systems-engineering project where little issues (vibration, torque balance, rotor airflow interactions, power delivery, control tuning)

turn into big issues the moment you bolt everything onto one frame.

This article is an in-depth, real-world, safety-first look at what it means to combine four smaller helicopter-style rotor systems into one larger quadcopter:

what gets easier, what gets harder, and why the “duct-tape-and-hope” approach is best left to comedy sketches.

It’s conceptual guidancenot a build tutorialand it’s written to help you understand the engineering tradeoffs, not to send you sprinting toward spinning blades.

Why the Idea Is So Tempting (and Why It’s Not Automatically Genius)

A quadcopter’s appeal is simple: distribute lift across four rotors, control attitude by varying thrust, and avoid the mechanical gymnastics

of a classic single-rotor helicopter (like a swashplate and tail rotor). If you already have multiple small helicopter-sized rotor “modules,”

it’s natural to imagine combining them into one platform that can lift more, carry bigger sensors, or fly with more stability.

In practice, you’re not just increasing lift. You’re increasing:

- Total mass (frame, wiring, mounts, reinforcements)

- Structural loads (bending, twisting, resonance)

- Control complexity (tuning becomes less forgiving)

- Energy risk (more power means higher consequences when something goes wrong)

The key mindset shift is this: a “larger quadcopter” is not four helicopters placed near each other.

It’s one aircraft with one center of gravity, one inertia profile, one control system, and one responsibility to behave predictably.

Helicopter vs. Quadcopter: Same Spinny Idea, Different Philosophy

The phrase “four smaller helicopters” can mean a few different things, but the engineering questions are similar.

A traditional RC helicopter rotor system often uses collective pitch (changing blade angle) and sometimes cyclic control to steer.

A typical quadcopter uses fixed-pitch props and changes motor speed to adjust thrust.

What changes when you go multirotor?

- Torque management: quadcopters usually alternate rotor directions (CW/CCW) so net torque cancels, reducing unwanted yaw.

- Control mixing: roll/pitch/yaw are generated by a flight controller distributing thrust changes across the four rotors.

- Mechanical simplicity (usually): fewer moving linkages compared to a single-rotor helicopter with swashplate mechanics.

If your “smaller helicopter” units use variable-pitch rotor heads, you’re in an interesting hybrid space:

variable pitch can produce faster thrust changes than waiting for motor RPM to spool up or down.

That can improve responsivenessbut it also adds mechanical complexity and more potential failure points.

The Core Math You Can’t Dodge: Thrust, Weight, and Disk Loading

Every flying machine eventually answers to the same boss: weight.

If your total thrust margin is small, your aircraft becomes “technically airborne” in the same way a toaster becomes “technically a hot air balloon”:

briefly, unpredictably, and not in a way you want to repeat.

Power-to-weight is the headline

In a quadcopter, the rotors must produce enough thrust to:

(1) hover, (2) climb, and (3) still have extra control authority for stability corrections.

The heavier you go, the more thrust you need, and the more power you pulloften nonlinearly.

Disk loading is the quiet villain

Disk loading is essentially how much weight is “assigned” to a given rotor disk area.

Lower disk loading generally means better hover efficiency (less induced power required),

which is why helicopters use big rotors and why efficient multirotors often look like “four fans with an opinion.”

When you combine four rotor systems into one aircraft, you might imagine you’re increasing disk area and improving efficiency.

But spacing and airflow interactions can eat into those gains if rotors are too close or if the frame blocks clean flow.

Rotor Interference: When Four Rotors Start Arguing in the Air

Rotors don’t just push down air politely; they create complex wakes.

Place multiple rotors near each other and their wakes can interactespecially in forward flight, during descent, or when the craft is pitching aggressively.

The result can be:

- Reduced efficiency (more power for the same lift)

- Uneven lift distribution (one corner “works harder”)

- Control weirdness (more tuning sensitivity, unexpected oscillations)

This is one reason why “bigger” multirotors often use wider rotor spacing, carefully planned layouts,

and lots of testing to see how real airflow differs from the clean diagrams in your imagination.

Structure and Vibration: The Part Everyone Underestimates

Small rotorcraft can be forgiving. Big ones are not. Once you connect four rotor systems to one frame, the frame becomes a musical instrument

that only plays one song: resonance.

Why vibration becomes a control problem

Quadcopter stability depends on clean sensor dataespecially from gyros and accelerometers.

Vibration can masquerade as motion, causing a flight controller to “correct” a movement that isn’t real,

which can spiral into oscillations, overheating, or a very un-fun lawn dart impression.

Common vibration sources in a “four-into-one” concept

- Rotor imbalance (tiny imbalance becomes huge at scale)

- Misalignment between modules (torsion and bending loads)

- Frame flex (changing geometry under thrust)

- Motor/gear harmonics (especially if rotor systems aren’t identical)

The practical takeaway: a larger quadcopter is as much a structures project as it is a flight-controls project.

If the frame behaves like a trampoline, no amount of software optimism will save you.

Control System Reality: “Motor Mixing” Isn’t MagicIt’s Math with Consequences

In a classic quadcopter layout, the flight controller translates desired roll, pitch, yaw, and thrust into four rotor commands.

That translation assumes predictable rotor response, consistent thrust curves, and symmetrical geometry.

“Turning four smaller helicopters into one larger quadcopter” challenges all three.

What makes control harder at larger scale?

- Higher inertia: a larger craft resists quick attitude changes, so control loops must be tuned differently.

- Slower actuator response: bigger rotors and heavier drivetrains may respond slower to command changes.

- Asymmetry creep: even slight differences between modules can create persistent bias.

If you’re using variable-pitch rotor heads, you can improve response bandwidthbut then the control problem becomes

“servo + pitch mechanics + aerodynamic hysteresis + motor dynamics,” which is… a lot.

(Technically exciting. Also the kind of exciting that requires careful validation.)

Power and Thermal: The Unsexy Stuff That Determines Whether It Works

Bigger quadcopters don’t just need more power; they need reliable power.

High current draw turns wiring, connectors, and electronics into critical components, not afterthoughts.

Heat becomes a design constraint, and voltage sag can turn “stable hover” into “mysterious wobble.”

Why “four small power systems” doesn’t automatically scale cleanly

- Load sharing: if one rotor system draws differently, it can unbalance the craft.

- Electrical noise: more power electronics can mean noisier sensor environments.

- Battery safety: higher-energy battery packs carry higher fire risk if mishandled or damaged.

This is also where responsible design meets responsible operations:

charging, storage, inspection, and damage protocols matter more as energy increases.

Redundancy and Failure Modes: What Happens When One Corner Has a Bad Day?

A quadcopter is elegant, but it’s not inherently tolerant of a full rotor failure the way some larger multirotors can be.

When one rotor loses significant thrust, the aircraft can lose controllability fast, depending on design and flight controller capabilities.

That’s why many heavy-lift designs move beyond four rotors (hex, octo, coaxial pairs) to improve fault tolerance.

If the mission demands “keep flying even if something fails,” a four-rotor configuration may not be the best match.

Safety and U.S. Rules: The Part You Don’t Want to Learn the Hard Way

If your larger quadcopter is flown in the United States, you’ll want to understand the difference between recreational rules and commercial rules,

plus requirements like safety knowledge testing and Remote ID compliance where applicable.

Two big buckets: recreational vs. Part 107

- Recreational flying: the FAA requires recreational flyers to take the TRUST safety test and follow applicable guidelines.

- Part 107 operations: if you’re flying for work or certain non-recreational purposes, the FAA’s remote pilot framework applies.

Remote ID is a real requirement for many aircraft

If you’re operating a drone that must be registered, FAA rules generally require operating in accordance with Remote ID requirements,

unless you meet an exception (for example, operating in a recognized identification area under specific conditions).

Community-based safety is not “optional vibes”

Organizations like the Academy of Model Aeronautics (AMA) publish safety codes and guidance used widely by model aviation communities.

Even if you’re not flying at a club field, the safety principles (visual line of sight, see-and-avoid, predictable operations)

are the foundation of responsible flight.

One more plain-English note: a “larger quadcopter” can cause serious injury or property damage.

If you’re learning, do it with experienced supervision, appropriate locations, and a safety culture that treats spinning rotors like the serious hazard they are.

Design Choices That Usually Work Better Than “Just Bolt Them Together”

The phrase “turning four smaller helicopters into one larger quadcopter” suggests reuseand reuse can be smart.

But smart reuse usually looks like:

1) Standardize modules (or accept endless troubleshooting)

When modules differeven slightlyyou get persistent trim issues and uneven loading.

Standardization reduces unknowns and makes tuning possible without turning your weekends into a detective series.

2) Design around the center of gravity

In multirotors, CG placement affects everything: control authority, efficiency, and stability.

A larger frame with a “wandering CG” is like shopping cart wheels that point in four directions.

3) Treat airflow as part of the airframe

Avoid layouts that force rotors to ingest turbulent air from arms, payloads, or each other.

Clean inflow supports consistent thrust, which supports consistent control.

4) Plan for testing that scales safely

Bigger aircraft should mean bigger emphasis on simulation, incremental validation, and controlled environments

not “full send on the first try.”

So… Is It a Good Idea?

It can beif the goal is learning, research, or carefully supervised engineering exploration.

Turning four smaller rotorcraft into one larger quadcopter is basically a crash course in:

distributed lift, rotor aerodynamics, vibration isolation, control theory, power electronics, and risk management.

But if the goal is simply “lift more,” there are often cleaner paths:

purpose-built multirotor frames, more rotors for redundancy, or designs optimized for disk loading and airflow.

Reusing helicopter-style modules can still make sense, especially if variable pitch is part of the strategy

just don’t underestimate the integration cost.

Experience Notes: What Makers Commonly Learn When Scaling Up (500+ Words)

People who experiment with larger multirotors often describe the experience as a blend of excitement and humility.

The first lesson is usually that “bigger” doesn’t feel like a simple multiplierit feels like a different category of machine.

A small craft might tolerate a slightly bent arm or a prop that’s “basically balanced.”

A larger craft responds by vibrating like a washing machine full of shoes and then demanding you reconsider your life choices.

A common early surprise is how quickly tiny inconsistencies become obvious in the air.

On paper, four identical lift modules should share the load evenly.

In reality, slight differences in rotor efficiency, drivetrain friction, or sensor noise can cause one corner to run hotter or work harder.

Builders often notice this indirectly: flight times come up short, one module sounds different, or the craft always wants to drift in the same direction.

That drift becomes a clue that “perfect symmetry” is something you must actively design and maintain, not something you get for free.

Another repeated theme is that vibration feels like a “software bug” until you realize it’s a “physics bug.”

Many makers start by adjusting controller settings, only to discover the controller was reacting to noisy measurements.

Once vibration is reducedthrough better balancing, stiffer structures, improved mounting, or cleaner mechanical alignmentthe craft suddenly behaves

as if someone upgraded the flight controller. That moment is memorable: the same control logic, the same sensors, but a quieter mechanical environment

transforms everything. It’s also why experienced builders tend to talk about airframes the way musicians talk about instruments:

structure affects signal, and signal affects performance.

People also learn that “integration” is a discipline of its own.

Four individual helicopters can each be tuned to fly acceptably, but once integrated, the combined aircraft has new dynamics:

different inertia, different coupling, different resonance, and sometimes new airflow problems caused by the frame and payload.

This can feel frustratinglike the project got worse after getting “more complete”until you recognize that the integration step creates a new system

that must be validated as its own aircraft.

On the practical side, makers commonly describe the psychological benefit of simulation and incremental testing:

it turns fear into data. Even when you’re not building a full system, modeling the craft’s expected thrust margin, checking the plausibility of hover power,

and visualizing control mixing can prevent expensive mistakes. The experience is similar to building a bridge:

you don’t “guess and pray” with the final loadyou sanity-check the numbers, then test progressively, and only then trust it.

Finally, the most valuable experience note is usually the least glamorous: safety culture scales faster than your frame does.

Larger multirotors push people toward better habitsclear work areas, careful inspection routines, conservative operating locations,

and respect for regulations and community guidelines. Many makers report that once they start thinking like an aviation operator

(not just a hobbyist), their projects get more reliable and more enjoyable. It’s hard to have fun when you’re anxious.

It’s easier to have fun when you’ve done the homework and the aircraft behaves like you planned it would.

Conclusion

Turning four smaller helicopters into one larger quadcopter is an idea with real engineering depth behind it.

It forces you to think like an aircraft designer: balance torque, manage disk loading, respect rotor interference,

build a structure that doesn’t lie to your sensors, and deliver power safely and consistently.

If you approach it as a learning projectconcept first, safety alwaysit can teach you more about flight than a dozen “easy builds.”

If you approach it as a shortcut to heavy lift, it can become an expensive reminder that physics does not accept IOUs.

Either way, the best outcome is the same: you finish with more knowledge, more respect for rotorcraft engineering,

and fewer dramatic lessons delivered at high RPM.