Table of Contents >> Show >> Hide

- Before You Build: Rules, Lines, and Underground Surprises

- Pick the Right Fence Type for Your Yard (and Your Future Self)

- Fence Planning That Prevents Fence Regrets

- Materials and Tools: The “Don’t Make Three Store Trips” Checklist

- Step-by-Step: Building a Wood Fence That Stays Straight

- Step 1: Lay out the fence line

- Step 2: Mark post locations

- Step 3: Dig post holes (depth matters)

- Step 4: Add gravel for drainage

- Step 5: Set corner, end, and gate posts first

- Step 6: Run a string line for the “perfectly straight” look

- Step 7: Set line posts

- Step 8: Attach rails/stringers

- Step 9: Install pickets or panels

- Step 10: Build and hang the gate

- Building a Fence on a Slope: Two Strategies

- Details That Make a Fence Last Longer

- Common Fence-Building Mistakes (So You Don’t Star in Them)

- When Hiring a Pro Might Be the Smartest DIY Move

- Real-World Fence Experiences (500+ Words of “Learn From This, Please”)

A fence is basically your home’s way of saying, “I love you… from over there.” It can add privacy, keep pets

contained, protect a garden from hungry visitors, and make your yard look finished instead of “we’re still

figuring life out.”

The good news: building a fence is absolutely doable with solid planning and patience. The honest news: the

ground does not care about your weekend schedule. This guide walks you through a smart, code-aware, straight-line

approach to DIY fence installationwithout turning your yard into a “modern art” exhibit.

Before You Build: Rules, Lines, and Underground Surprises

1) Confirm property lines (because “pretty sure” is not a survey)

If your fence is near a boundary, verify where the property line actually is. A fence built six inches onto the

wrong side can become an expensive neighborhood soap opera. If you’re not sure, consider checking your plat,

calling your city/county, or hiring a surveyorespecially if the line is disputed or unclear.

2) Check permits, height limits, and HOA rules

Fence rules vary wildly: some places limit front-yard fence height, require certain materials, or have setbacks

from sidewalks and easements. HOAs may care about style, color, and which side faces out. Do the paperwork first;

it’s much less painful than “redoing the fence because the inspector said so.”

3) Call 811 (and think about private lines)

Any digging can hit utilities. In the U.S., contact 811 before you dig so participating utilities can mark

underground lines. Also know that some privately owned lines (like irrigation, landscape lighting, or invisible

pet fences) may not be marked through the standard processso plan carefully.

Safety note: Fence building can involve heavy lifting, digging, and power tools. If you’re under 18,

do this with a responsible adult supervising and follow all tool instructions and local safety requirements.

Pick the Right Fence Type for Your Yard (and Your Future Self)

Wood privacy fence

Classic, customizable, and great for privacy. It needs maintenance (stain/seal/paint), and boards can warp if you

ignore them like last year’s gym membership.

Picket fence

More decorative than fortress-like. Great for defining space, less great for hiding a messy patio chair

collection.

Vinyl fence

Low maintenance and clean-looking. Costs more upfront, but you won’t spend weekends staining it. Installation is

often “systems-based” (posts + panels + brackets) and may be less forgiving about layout being perfectly square.

Chain-link fence

Budget-friendly, durable, and practical. Not everyone loves the look, but it’s hard to beat for “I just need a

boundary that works.”

Aluminum/steel

Attractive and durable; great for visibility around pools or landscaping. Usually pricier, but can look

high-end.

Fence Planning That Prevents Fence Regrets

Sketch first, dig later

Draw your yard and mark the fence route. Identify gates, corners, and any obstacles (trees, roots, slopes,

boulders, sprinklers). A simple plan helps you buy the right materials and keep your build day from becoming

“creative improvisation.”

Decide where the “pretty side” goes

Many neighborhoods expect the finished side to face outward. It looks better and keeps everyone on speaking

terms. Also: check your HOA or local rules if you have them.

Example: estimating posts and panels

Let’s say you’re fencing 120 feet with 8-foot panels. Divide 120 by 8 = 15 panels. Panels need posts between

them, plus end posts. So you’ll typically need about 16 posts (and more if you add gates or extra corners). If

you’re doing a “stick-built” fence (rails + pickets), you’ll still use post spacingoften 6 to 8 feet depending

on fence height, wind exposure, and design.

Materials and Tools: The “Don’t Make Three Store Trips” Checklist

Common materials

- Posts: pressure-treated wood or metal posts rated for ground contact

- Rails/stringers: typically 2x4s for many wood fences

- Pickets/boards or panels: choose style (dog-ear, straight, shadowbox, etc.)

- Fasteners: exterior-rated screws/nails; corrosion-resistant for treated lumber

- Concrete mix: for setting posts (especially corners, ends, and gates)

- Gravel: for drainage at the bottom of post holes

- Gate hardware: hinges, latch, drop rod (if needed), and possibly wheel support

- Finish: stain, sealer, or paint designed for exterior wood (if using wood)

Tools (varies by fence type)

- Measuring tape, stakes, string line, marking paint

- Level (a post level is handy), square

- Post hole digger or auger

- Shovel, tamper, wheelbarrow/bucket

- Drill/driver, saw (as needed), clamps

- Safety gear: gloves, eye protection, hearing protection

Step-by-Step: Building a Wood Fence That Stays Straight

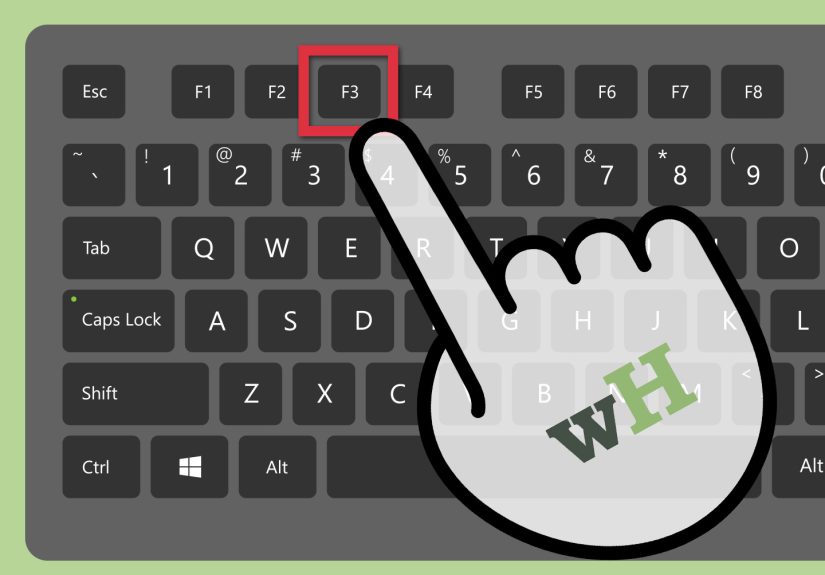

Step 1: Lay out the fence line

Pound stakes at corners and run string lines between them. Measure diagonals if you’re building a rectangular

enclosurematching diagonals helps confirm it’s square. Mark gate locations clearly.

Step 2: Mark post locations

Mark posts based on panel length (often 8 feet) or your chosen spacing. Plan for stronger posts at corners and

gates. A gate post carries more force than a standard line post, so don’t treat it like “just another post.”

Step 3: Dig post holes (depth matters)

A common approach is setting posts roughly one-third of the post length into the ground, adjusting for fence

height and local frost line. In colder climates, posts need to extend below the frost line to reduce heaving.

Hole diameter is often wider than the post to allow for gravel, adjustment, and concrete where needed.

Step 4: Add gravel for drainage

Put a few inches of gravel at the bottom of each hole and tamp it. This helps with drainage so water doesn’t sit

against the post like it’s trying to speed-run rot.

Step 5: Set corner, end, and gate posts first

These are your anchors. Plumb each post (perfectly vertical) and brace it so it doesn’t move while you set it.

If you’re using concrete, slope the top of the concrete away from the post so water runs off.

Step 6: Run a string line for the “perfectly straight” look

Once your end posts are set, stretch a string line along the fence run to align the intermediate posts. This is

the step that separates “professionally installed” from “it’s… charming.”

Step 7: Set line posts

With the string line as your guide, set the rest of the posts. Take your time with plumb and height. If your

posts aren’t right, everything after this becomes a gymnastics routine.

Step 8: Attach rails/stringers

Most privacy fences use two or three horizontal rails depending on fence height and design. Keep rails level or

intentionally stepped for slopes. Use exterior-rated fasteners and hardware appropriate for treated lumber.

Step 9: Install pickets or panels

For panels: fasten panels to posts per the system instructions and keep the tops aligned with a level line. For

pickets: use a spacer to keep gaps consistent (or overlap boards for a shadowbox look). Check alignment every few

boards so you don’t drift into “wave fence” territory.

Step 10: Build and hang the gate

Gates sag when they’re underbuilt. Use sturdy posts, quality hinges, and a braced gate frame. If the gate is

wide, consider hardware that supports the weight (like a wheel or heavy-duty hinge setup). Make sure the latch

height is comfortable and the swing clears the ground.

Building a Fence on a Slope: Two Strategies

Option 1: Stepped fence

Each section stays level, and the fence “steps” down the hill. This is common for panel fences and creates a

staircase effect at the bottom edge.

Option 2: Racked (contoured) fence

The fence follows the slope more smoothly. This can look cleaner, but it takes careful measuring and

often works best with certain designs (like adjustable panels or custom picket layouts).

Details That Make a Fence Last Longer

Use the right fasteners for treated wood

Many pressure-treated woods can be corrosive to standard fasteners over time. Choose hot-dip galvanized or

stainless steel fasteners/connectors as recommended for treated lumber applications.

Keep wood out of “wet traps”

Avoid burying non-rated wood. Keep vegetation trimmed away from fence boards and posts, and don’t let soil or

mulch pile up against the wood. Water + wood + time = rot’s favorite recipe.

Finish it (especially if you want it to look good in two years)

A stain or sealer helps wood handle sun and moisture. If painting, prep properly and choose a product made for

exterior wood. Maintenance is boring, but so is rebuilding a fence early.

Common Fence-Building Mistakes (So You Don’t Star in Them)

- Skipping layout: eyeballing is not a measuring system.

- Weak gate posts: gates magnify small mistakes and love to sag.

- Bad drainage: standing water around posts shortens fence life.

- Wrong fasteners: cheap hardware can fail early with treated wood.

- Ignoring slope strategy: decide “stepped” vs. “racked” before you set posts.

- Not calling 811: utility strikes are dangerous and expensive.

When Hiring a Pro Might Be the Smartest DIY Move

If your yard is extremely rocky, your fence crosses complex slopes, you need a long run with multiple gates, or

local rules are strict, getting professional help can save time and rework. You can also mix approaches: hire out

post setting (the toughest part) and do rails/pickets yourself.

Real-World Fence Experiences (500+ Words of “Learn From This, Please”)

People who build their first fence often say the same thing afterward: “I thought the hard part would be

attaching the boards.” Then they meet the actual hard part: the ground. One common experience is discovering that

your “soft soil” is actually a museum of buried rocks. The solution isn’t heroic stubbornnessit’s adjusting your

plan. Some DIYers switch from a manual post hole digger to renting an auger, others widen the hole slightly, and

many learn the value of digging a little, clearing spoil, then digging more. It’s slower, but it’s also how you

avoid turning a Saturday into a three-day saga.

Another classic moment: the first time someone stretches a string line and realizes their “straight fence line”

is actually shaped like a gentle banana. This usually happens because the yard has subtle curves, landscaping

edges, or a property line that isn’t parallel to the house. The best takeaway from this experience is that layout

isn’t busyworkit’s the project. Homeowners who take an hour to stake corners, re-measure, and confirm the gate

swing often finish with a fence that looks intentional instead of accidental.

Gates provide their own set of life lessons. Many DIY builders report that their gate looked perfect on the

groundthen sagged after a week like it got emotionally attached to gravity. The fix is almost always the same:

beefier hardware, stronger gate posts, and a properly braced frame. The “experience-based” wisdom here is to

overbuild gates compared to the rest of the fence. A fence can be slightly imperfect and still look great. A gate

that drags is a daily reminder of your choices.

Weather is another repeat character in fence stories. Someone pours concrete for posts, then a sudden rainstorm

shows up like an uninvited guest with a plus-one. The practical lesson: check the forecast, stage materials, and

brace posts well. Many DIYers also learn to work in smaller phasesset posts one day, rails another, pickets

afterso the project doesn’t depend on one flawless stretch of perfect weather.

Neighbor interactions can be surprisingly positive… or surprisingly not. Homeowners often share that a quick

conversation beforehand saved major tension laterespecially for boundary-adjacent fences or shared costs. The

best “experience” tip is simple: communicate early, show your plan, and confirm which side faces out. It doesn’t

guarantee harmony, but it drastically reduces the odds of an awkward backyard standoff.

Finally, many fence-builders talk about the satisfaction of the last board going up. The yard feels different:

more private, more polished, more “ours.” And almost everyone says they’d do two things differently next time:

(1) buy a little extra material for mistakes and odd cuts, and (2) spend more time on post alignment. That’s the

heart of fence building experience in one sentence: your fence is only as straight and sturdy as your postsand

your patience.