Table of Contents >> Show >> Hide

- Before You Start: What a “Good” Gravel Driveway Actually Is

- Tools and Materials Checklist

- Step-by-Step: How to Build a Gravel Driveway

- Plan the layout, width, and turning space

- Measure and calculate gravel quantities

- Strip vegetation and excavate to depth

- Shape the subgrade for drainage (crown or cross-slope)

- Install geotextile fabric (recommended in many situations)

- Add the base layer (the strength layer)

- Add the middle layer (the “locks together” layer)

- Add the top layer (the “looks good and drives well” layer)

- Install edging (optional, but it saves your sanity)

- Final grading and a “test drive”

- Gravel Types: What to Ask the Rock Supplier (Without Sounding Like a Rock Influencer)

- Drainage Upgrades That Make Gravel Driveways Last Longer

- Maintenance: Keep It Nice Without Babysitting It

- Cost Snapshot (Because Someone Will Ask)

- Real-World Lessons from the Gravel Driveway Trenches (Experience Section)

A gravel driveway is one of those rare home projects that can be affordable, good-looking, and surprisingly durableas long as you build it like a tiny road and not like a giant sandbox.

The secret sauce isn’t the gravel you see. It’s the stuff you don’t: the base, the drainage shape, and the compaction.

This guide walks you through planning, digging, layering, shaping, and maintaining a gravel driveway that won’t turn into a muddy, rutted regret after the first heavy rain.

Along the way, you’ll get “picture prompts” (what you’d want to photograph at each step), plus real-world tips that DIYers learn the hard wayso you don’t have to.

Before You Start: What a “Good” Gravel Driveway Actually Is

A solid gravel driveway is a layered system:

stable subgrade (your native soil, properly shaped),

separation (often geotextile fabric),

a compacted base (larger crushed stone that locks together),

and a surface layer (smaller, driveable stone).

It’s also shaped to shed water, usually with a gentle crown (high in the middle) or a consistent cross-slope.

If your driveway fails, it’s usually because water lingers and softens the base, or the gravel mixes into the soil and disappears like snacks at a movie night.

Your mission: keep water moving and keep layers separated.

Tools and Materials Checklist

Tools

- Measuring tape, marking paint, stakes, mason’s string

- Shovel, rake (a landscape rake is your new best friend)

- Wheelbarrow (or a strong friend who owes you a favor)

- Plate compactor (rent), or a vibratory roller for larger drives

- Garden hose or sprayer for light moisture during compaction

- Work gloves, safety glasses, hearing protection

Materials

- Geotextile driveway fabric (optional but strongly recommended in many soils)

- Base stone (often 2"–3" crushed stone or road base, depending on local availability)

- Middle layer (commonly a well-graded crushed stone/“crusher run”/“road base” blend)

- Top layer (often #57 stone or similar, typically around 3/4" nominal size, angular)

- Edging (optional but helpful): pavers, cobblestone, pressure-treated timbers, steel edging

Call-before-you-dig

Always contact your local utility locating service (in the U.S., dialing 811 is common) before excavation.

Hitting a utility line is a fast way to turn a driveway project into a “Why is my weekend on fire?” story.

Step-by-Step: How to Build a Gravel Driveway

-

Plan the layout, width, and turning space

Start with how vehicles actually move. A common single-car driveway is around 10–12 feet wide; for comfortable two-way passing or two-car width, you may want 16–20 feet.

Include turning/parking pads if you hate three-point turns (and your lawn hates them too).Think about drainage now, not after the first puddle becomes a seasonal pond. The driveway should slope away from buildings and avoid funneling runoff toward foundations.

Picture idea: A wide shot of the proposed driveway path marked with stakes and string, showing where it meets the road and the garage. -

Measure and calculate gravel quantities

Gravel is sold by the ton or cubic yard. Your supplier can convert, but it helps to estimate yourself.

Use this quick method:- Area (sq ft) = length × width

- Volume (cubic ft) = area × depth (in feet)

- Cubic yards = cubic ft ÷ 27

Example: 12 ft × 60 ft = 720 sq ft. A 4" layer is 0.333 ft.

Volume = 720 × 0.333 ≈ 240 cubic ft. Cubic yards = 240 ÷ 27 ≈ 8.9 yd³.

Do that for each layer.Picture idea: A photo of your sketch with dimensions and the layer thicknesses written in (yes, like a cooking recipe for rocks). -

Strip vegetation and excavate to depth

Remove sod, roots, and topsoil. Organic material decomposes and settlesbad news under a driveway.

Excavation depth depends on soil, climate, and vehicle loads, but many residential builds target a multi-layer section that can total roughly 8–12 inches (or more in weak soils).If your area freezes hard in winter or your subsoil is clay that holds water, plan for extra depth and better drainage shaping.

If you’re not sure, go deeper rather than “optimistic.”Picture idea: Excavation trench showing clean subsoil, with a tape measure in-frame to document depth. -

Shape the subgrade for drainage (crown or cross-slope)

This is where many DIY driveways lose the plot. A flat driveway is a puddle-friendly driveway.

You want water to move off the surface and away from the road base.Two common approaches:

- Crowned: highest in the center, gently sloping to both edges.

- Cross-sloped: consistently sloping to one side (useful on hillsides).

Keep grades gentle enough for traction and comfortable driving, but effective enough to prevent standing water.

If your driveway ties into a public road or ditch, check local rules about driveway entrances and culverts.Picture idea: A side view of the shaped subgrade, with string lines showing a slight crown. -

Install geotextile fabric (recommended in many situations)

Geotextile fabric helps separate stone from soil, reducing “stone migration” into the subgrade and improving long-term stability.

Lay it directly on the prepared subgrade, overlap seams, and extend it slightly beyond the driveway edges before trimming.Tip: This is not the time for flimsy “weed cloth.” Driveway fabric is made for loads and separation.

Picture idea: Fabric rolled out neatly over the full driveway footprint, with overlaps visible at seams. -

Add the base layer (the strength layer)

The base is usually a larger crushed stone or a well-graded road base material that can compact into a tight, interlocked structure.

Spread it in lifts (thin layers), not one giant dump-and-hope pile.Compact each lift thoroughly. A plate compactor works for smaller drives; a roller is better for long lanes.

If the material is bone dry and dusty, a light mist of water can help it compactthink “damp sandcastle,” not “swamp.”Picture idea: Plate compactor in action on the first base lift, with a clean edge line visible. -

Add the middle layer (the “locks together” layer)

Many successful gravel driveways use a middle layer of smaller, well-graded crushed stone (often called crusher run, road base, or similar),

which compacts tightly and creates a stable platform for the top layer.Again: spread, shape, compact. If you skip compaction, your tires will compact it for youby carving ruts like an artist who only paints with frustration.

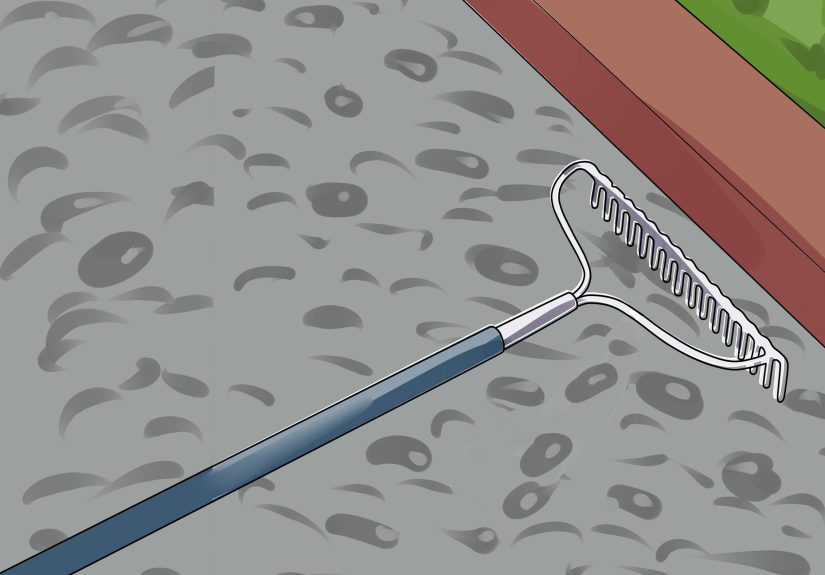

Picture idea: A rake smoothing the middle layer, showing a consistent crown before compaction. -

Add the top layer (the “looks good and drives well” layer)

The top layer is what you see and feel. Angular stone tends to stay put better than round stone.

A common choice is a 3/4" nominal crushed stone (like #57), but local names varyask your supplier for a driveway-appropriate surface stone.Keep the top layer thick enough to cover and protect the layers below, but not so deep that it feels like driving through loose marbles.

Aim for a tidy, even surface you can rake back into place.Picture idea: Finished driveway close-up: angular stone on top, with a crisp edge and no exposed fabric. -

Install edging (optional, but it saves your sanity)

Gravel loves to migrate. Edging gives it boundaries and makes maintenance easier.

Options include cobblestones set in concrete, pavers, pressure-treated timbers, or steel edging.Edging is especially useful on curves, slopes, and anywhere you’ll be snow-blowing or plowing.

Picture idea: A curve with edging installed, showing gravel neatly contained after raking. -

Final grading and a “test drive”

Walk the driveway slowly and look for low spots. Hose it lightly and watch where water wants to sit.

Fix tiny problems nowbecause tiny problems are adorable today and expensive next spring.Then do a gentle test drive. If the surface waves, shifts, or feels soft, you likely need more compaction or a better-shaped base.

Picture idea: Water from a hose running off the surface evenly, with no big puddles forming.

Gravel Types: What to Ask the Rock Supplier (Without Sounding Like a Rock Influencer)

Your supplier will have local names, but you can ask smart questions:

- “Is this angular crushed stone or round river gravel?” Angular usually stays put better.

- “Is this material well-graded?” Mixes with fines compact tighter for base layers.

- “What’s the typical driveway top stone around here?” They’ll know what works locally.

- “Can you deliver and tailgate spread?” Tailgating can save serious labor on long runs.

Avoid using pea gravel as a main driveway surface unless the design is specifically meant for it (or you enjoy the sensation of driving on ball bearings).

Pea gravel is great for patios and paths, but vehicle tires can push it around more easily.

Drainage Upgrades That Make Gravel Driveways Last Longer

A gravel driveway is basically a stormwater negotiation. You’re telling rain, “You may passbut you may not stay.”

Helpful upgrades

- Maintain a crown or cross-slope: keeps water moving off the driving surface.

- Keep ditches open: blocked ditches are a puddle subscription service you don’t want.

- Install a culvert where needed: if a ditch line crosses your entrance, a culvert prevents washouts.

- Consider permeable stabilization grids: especially on slopes or weak soils, grids can reduce rutting and keep stone in place.

If you’re in an area with heavy runoff or you’re trying to reduce stormwater impacts, permeable driveway systems can help manage runoff by letting water infiltrate through the surface into a stone base that temporarily stores water.

Maintenance: Keep It Nice Without Babysitting It

Gravel driveways don’t need constant attentionbut they do need the right kind of attention at the right time.

Think “seasonal tune-up,” not “daily obsession.”

Quick maintenance routine

- Rake displaced stone back into place after heavy rain, snowplowing, or lots of turning movements.

- Refresh the crown before potholes start collecting water.

- Topdress thin areas with matching stone rather than dumping random gravel leftovers.

- Control weeds smartly (edging, proper fabric, and removing wind-blown soil helps).

Common problems and what they usually mean

- Potholes: water pooling + soft base. Fix drainage shape first, then patch with compactable material.

- Ruts: inadequate base thickness/compaction, weak subgrade, or persistent moisture. Consider fabric and rebuilding low sections.

- Washboarding (ripples): traffic + dry loose surface + wrong grading. Reshape and compact; sometimes different surface stone helps.

- Gravel “disappearing”: stone mixing into soil because separation or base structure is missing (fabric helps here).

Cost Snapshot (Because Someone Will Ask)

Gravel driveways are typically cheaper than asphalt or concrete, but costs swing based on excavation, base thickness, stone type, delivery distance, and whether you rent equipment.

As a rough national ballpark, you may see ranges from about $1–$10 per square foot, with many typical installs clustering in the lower-to-middle part of that range.

For long rural driveways with major earthwork, costs can climb quickly.

If you want to save money without sacrificing longevity, spend on the base and drainage first, then choose a sensible top stone.

A cheap driveway that fails is just an expensive driveway with a time delay.

Real-World Lessons from the Gravel Driveway Trenches (Experience Section)

The first time you build a gravel driveway, you’ll probably have a moment where you stare at a pile of stone and wonder if you accidentally ordered “one mountain.”

That’s normal. Gravel has a magical ability to look like “not much” when it’s in a truck and “a geological event” when it’s in your yard.

The trick is to treat it like a process, not a pile.

One of the biggest “aha” moments people have is learning that the driveway’s shape matters more than the driveway’s beauty.

A perfectly raked surface that’s flat as a pancake will still turn into potholes, because water will sit, soak, and soften everything underneath.

When you add even a subtle crown, you can literally watch water leave the party instead of moving in permanently.

A hose test helps: if water wanders to the edges and disappears, you’re winning.

If it forms puddles, your driveway is quietly auditioning for the role of “future headache.”

Compaction is another lesson people learn with their backs.

Spreading stone is work, but spreading stone that later sinks and ruts is work twice.

Renting a plate compactor can feel like an annoying extra stepuntil you see how the surface firms up and stops behaving like loose cereal.

Compacting in lifts is key: if you dump 8 inches of base stone and compact the top, the bottom layer doesn’t magically get the memo.

Thin layers compact better, lock together better, and stay put better.

The fabric debate comes up in almost every driveway conversation.

In sandy, well-draining soil, you might get away without fabric.

In clay, soft ground, or any area with persistent moisture, separation fabric can be the difference between a driveway that lasts and a driveway that slowly eats gravel like it’s paid by the ton.

The most common mistake is using lightweight landscape “weed cloth” and expecting it to behave like road construction fabric.

If you’re using fabric, use driveway-rated geotextile and install it directly on the prepared subgrade.

It’s not glamorous, but neither is ordering “just one more load” every year.

Curves and slopes teach humility. On a slope, turning tires can shove surface gravel downhill, especially with round stone.

That’s where edging, better top material (angular), and sometimes stabilization grids can help.

People often try to “fix” a slope by adding more gravel, but the better fix is shaping and structure: keep runoff controlled, maintain a consistent grade, and use containment.

Even snow removal mattersmetal plow blades can peel off your top layer if you scrape too aggressively.

A slightly raised plow shoe or a gentler first pass can save your surface stone from migrating into your lawn.

Lastly, the most underrated driveway tool isn’t a machineit’s timing.

Do light maintenance when the driveway is slightly damp and cooperative, not when it’s bone dry and dusty or soaked and squishy.

After a good rain (not a flood), raking and reshaping is easier, compaction works better, and you can spot drainage issues quickly.

A gravel driveway doesn’t need constant attention, but it does reward the homeowner who checks it twice a year and makes small corrections before the big problems show up.

If you treat it like a low-drama relationshipclear boundaries (edging), good communication (drainage), and occasional support (topdressing)it’ll stick with you for the long haul.